Citation

Fernandes, F.; Manari, S.; Aguayo, M.; Santos, K.; Oey, T.; Wei, Z.; Falzone, G.; Neithalath, N.; Sant, G. Cement and Concrete Composites 2014, 51, 14-26.

Fernandes, F.; Manari, S.; Aguayo, M.; Santos, K.; Oey, T.; Wei, Z.; Falzone, G.; Neithalath, N.; Sant, G. Cement and Concrete Composites 2014, 51, 14-26.

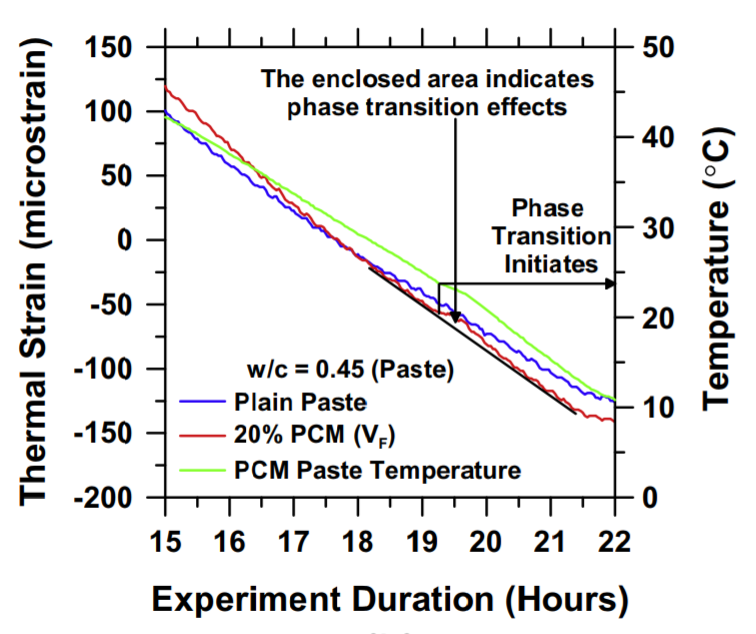

Temperature changes driven by hydration reactions and environmental loading are a leading cause of thermal cracking in restrained concrete elements. This work describes preliminary investigations on the use of microencapsulated phase change materials (PCMs) as a means to mitigate such thermal cracking. Special attention is paid to quantify aspects of: heat absorption and release, the development of unrestrained/restrained thermal stresses and strains and the mechanical properties including: compressive strength, elastic modulus and fracture behavior. First, PCMs incorporated in cementitious systems absorb and release heat, which scales as a function of their dosage and enthalpy of phase change. Second, for restrained and unrestrained conditions and for equal temperature change, the thermal deformation and stresses developed are noted to be similar to a plain cement system independent of the PCM dosage. However, PCM additions are noted to reduce the rate of deformation and stress development so long as the phase transition is active. Third, while the presence of PCMs does depress the compressive strength and elastic modulus (in increasing proportion with dosage), the fracture toughness is impacted to a lesser degree. While of a preliminary nature, the studies highlight a novel means of exploiting phase transitions to control thermal stress evolutions in restrained elements.