Citation

Ketel, S.; Falzone, G.; Wang, B.; Washburn, N.; Sant, G. Cement and Concrete Composites 2018, available online.

Ketel, S.; Falzone, G.; Wang, B.; Washburn, N.; Sant, G. Cement and Concrete Composites 2018, available online.

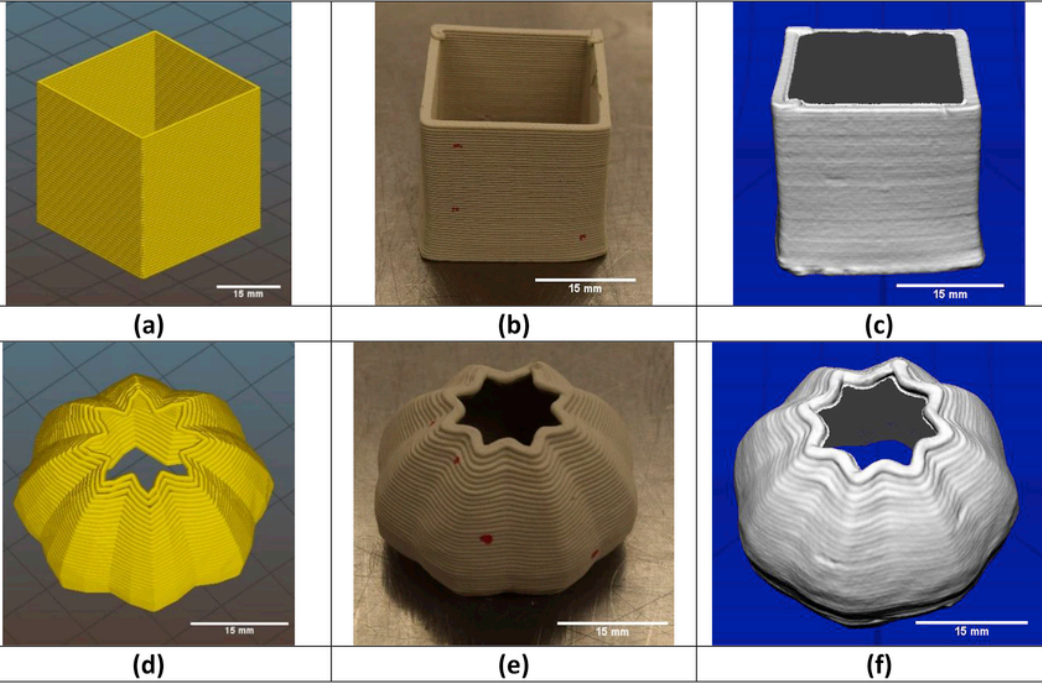

While the field of 3D-printing (3DP; formally known as additive manufacturing) has increasingly matured, its use in large-scale applications, e.g., building and infrastructure construction, remains limited. Although layer-wise slurry deposition/extrusion (LSD/E) methods are amenable to scale-up and offer versatility in terms of the materials that can be printed (i.e., “inks” that can be used), there is a lack of quantitative metrics to assess the geometrical attributes of printed components vis-à-vis their 3D-CAD (computer-aided design) inputs. To address this limitation, we present an original method to assess the external geometrical attributes of 3D-printed components using laser triangulation-based 3D-scanning. Significantly, a printability index (0 ≤ Ip ≤ 1, unitless) is presented which compares the overall geometric fidelity of the printed specimen to its CAD input. By adjusting the rheology of a model silicate-based slurry, we examine the relationships between slurry rheology, shrinkage and printability. The printability index offers a quantitative basis for assessment and quality control of 3D-printed components, while helping to develop an improved understanding of how slurry behavior, and optimizations therein can maximize printability.