Citation

Okoronkwo, M. U.; Falzone, G.; Wada, A.; Franke, W.; Neithalath, N.; Sant, G. J. Mater. Civ. Eng., 2018, 30(7): 04018122.

Okoronkwo, M. U.; Falzone, G.; Wada, A.; Franke, W.; Neithalath, N.; Sant, G. J. Mater. Civ. Eng., 2018, 30(7): 04018122.

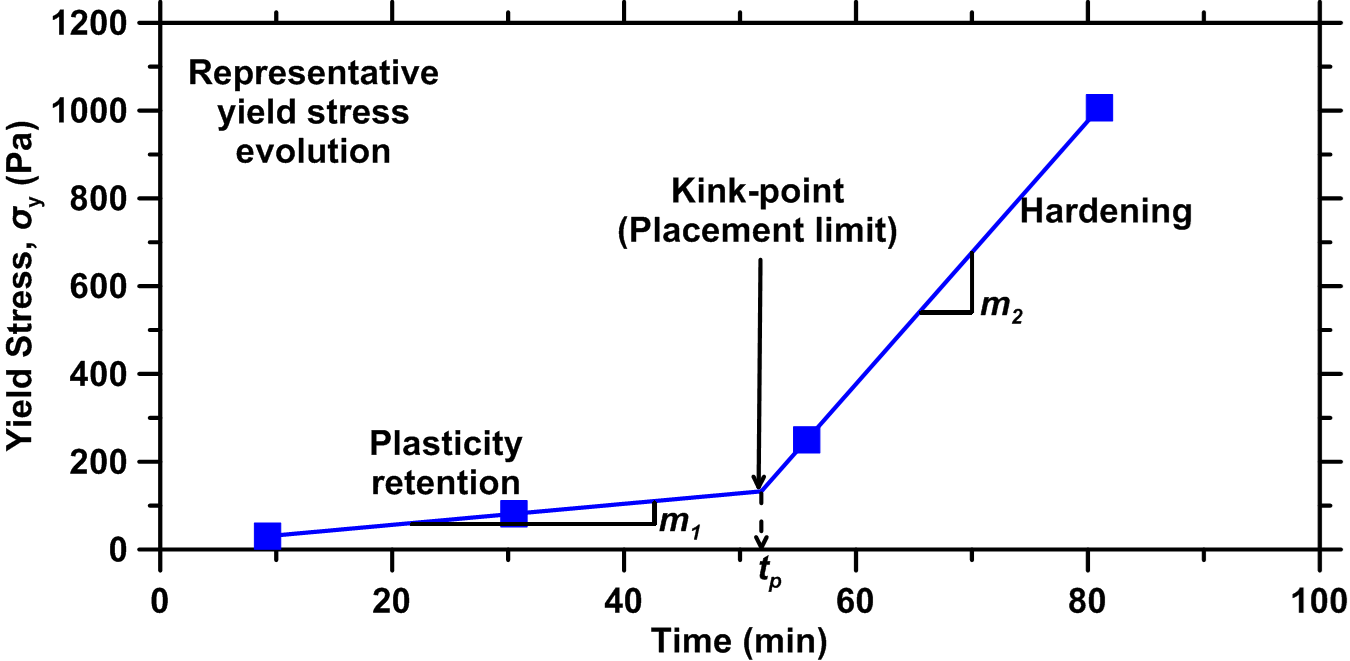

Chemical admixtures are often added to concentrated cementitious suspensions in an effort to adjust their (1) rheology, i.e., yield stress and viscosity; (2) time of set, i.e., when plasticity is lost; and (3) hardening rate. Although the first adjustment is affected by dosage of dispersants, the subsequent two adjustments are made by dosing chemical additives that alter the binder’s reaction rate. To ensure desirable field performance, e.g., at subambient temperatures, dispersants and reaction rate enhancers may be dosed simultaneously. In such cases, it is critical to ensure that the dosed additives are compatible with each other. To assess such admixture compatibility and synergy, an original rheology-based method is developed. The method involves assessing the yield stress and plastic viscosity of cementitious suspensions with and without admixtures over a wide strain rate range (10−4≤γ˙≤102). Three fluidity parameters are examined, including (1) plasticity retention; (2) placement limit, i.e., time at which pumpability/pourability is lost; and (3) the rate of hardening following loss of plasticity. To provide a basis of comparison, each of these parameters is assessed relative to neat cement suspensions, across a range of liquid-to-solid ratios (by mass). The method is demonstrated for cementitious suspensions dosed with polycarboxylate ether (PCE) dispersants and calcium nitrate (CN), a set accelerator. The results highlight a means to identify dispersant/set accelerator combinations (or more generally, chemical admixture combinations) that yield optimal synergistic benefits.