Citation

Wei, Z.; Wang, B.; Falzone, G.; La Plante, E. C.; Okoronkwo, M. U.; She, Z.; Oey, T.; Balonis, M.; Neithalath, N.; Pilon, L.; Sant, G. Journal of CO2 Utilization 2018, 23, 117-127.

Wei, Z.; Wang, B.; Falzone, G.; La Plante, E. C.; Okoronkwo, M. U.; She, Z.; Oey, T.; Balonis, M.; Neithalath, N.; Pilon, L.; Sant, G. Journal of CO2 Utilization 2018, 23, 117-127.

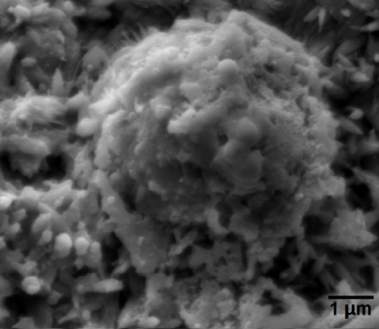

The production of ordinary portland cement (OPC) is a CO2 intensive process. Specifically, OPC clinkering reactions not only require substantial energy in the form of heat, but they also result in the release of CO2; i.e., from both the decarbonation of limestone and the combustion of fuel to provide heat. To create alternatives to this CO2 intensive process, this paper demonstrates a new route for clinkering-free cementation by the carbonation of fly ash; i.e., a by-product of coal combustion. It is shown that in moist environments and at sub-boiling temperatures, Ca-rich fly ashes react readily with gas-phase CO2 to produce robustly cemented solids. After seven days of exposure to vapor-phase CO2 at 75 °C, such formulations achieve a compressive strength of around 35 MPa and take-up 9% CO2 (i.e., by mass of fly ash solids). On the other hand, Ca-poor fly ashes due to their reduced alkalinity (i.e., low abundance of mobile Ca- or Mg-species), show limited potential for CO2 uptake and strength gain—although this deficiency can be somewhat addressed by the provision of supplemental/extrinsic Ca agents. The roles of CO2 concentration and processing temperature are discussed, and linked to the progress of reactions and the development of microstructure. The outcomes create new pathways for achieving clinkering-free cementation while enabling the beneficial utilization (“upcycling”) of emitted CO2 and fly ash; i.e., two abundant, but underutilized industrial by-products.